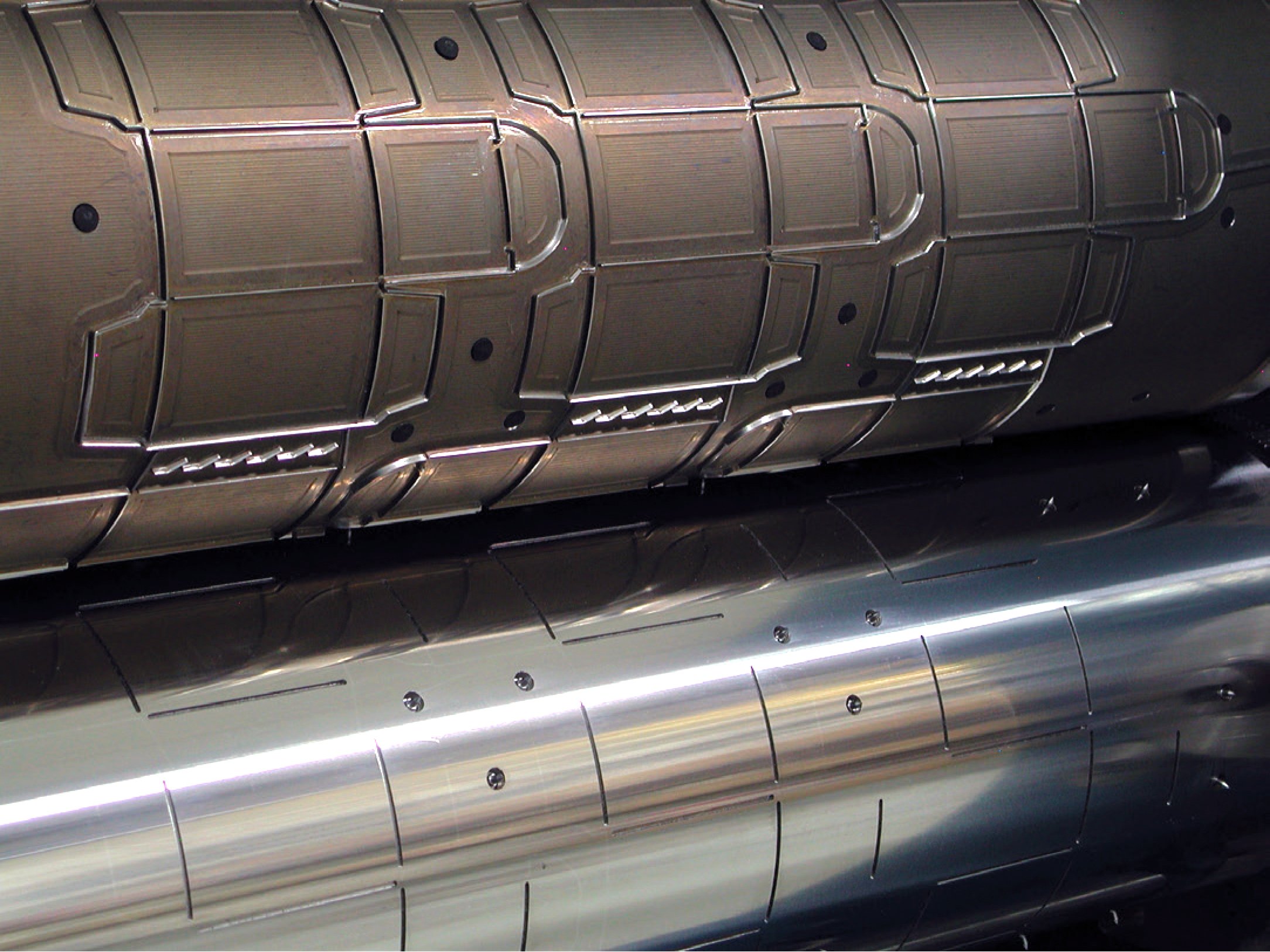

Superior Quality: The Power of Midway for Rotary Dies, Gears & Anvils

Discover the advantages of sourcing all your rotary die, gear, and anvil pieces from Midway to maintain consistent quality in your production process.

The Importance of Consistent Quality in Production Processes

Consistent quality is crucial in production processes as it ensures that the end products meet the desired standards and specifications. When it comes to rotary dies, gears, and anvil pieces, maintaining the same level of quality throughout the production process is of utmost importance. By having a single manufacturer for these components, businesses can achieve their desired consistency in quality.

When all components come from the same manufacturer, say goodbye to the headache of dealing with quality variations from different suppliers. This guarantees that your rotary dies, gears, and anvil pieces are all crafted to top-notch standards, resulting in a smoother and more effective production process. Consistent quality not only cuts down on rejections, rework, and scrap but also leads to cost savings and boosts overall productivity.

Moreover, consistent quality in rotary dies, gear, and anvil pieces contributes to the overall quality of the end products. When all the components are precisely manufactured and fit together seamlessly, it enhances the performance and functionality of the final product. This is particularly important for businesses that rely on rotary dies for intricate cutting and shaping processes, as any deviation in quality can lead to subpar results.

In summary, maintaining consistent quality in production processes by using the same manufacturer for rotary die, gear, and anvil pieces is essential for businesses. It ensures reliability, efficiency, cost savings, and improved overall productivity, while also enhancing the quality of the end products.

Benefits of Having a Single Manufacturer for Rotary Die, Gear, and Anvil Pieces

There are several benefits to having a single manufacturer for rotary die, gear, and anvil pieces in the production process.

Firstly, it ensures consistent quality throughout the manufacturing process. As mentioned earlier, by sourcing all these components from the same manufacturer, businesses can eliminate variations in quality that may arise from using different suppliers. This leads to a more reliable and efficient production process, with reduced rejections, rework, and scrap.

Secondly, having a single manufacturer simplifies the supply chain and reduces logistical complexities. Businesses can enjoy streamlined communication, shorter lead times, and better coordination when all the components are sourced from a single source. This not only saves time but also reduces the risk of delays and disruptions in the production process.

Additionally, working with a single manufacturer for rotary die, gear, and anvil pieces allows for better customization and compatibility. The manufacturer can understand the specific requirements of the business and tailor the components accordingly. This ensures a perfect fit and optimal performance, leading to improved overall product quality.

In summary, the benefits of having a single manufacturer for rotary die, gear, and anvil pieces include consistent quality, simplified supply chain, better customization, and improved overall product quality.

Midway: A Trusted Partner for Superior Quality

When it comes to sourcing rotary die, gear, and anvil pieces, Midway is the best choice for businesses in need of superior quality. With years of experience and expertise in the industry, Midway has established itself as a trusted partner for businesses across various sectors.

One of the key reasons why Midway stands out is its ISO 9001 QMS Certification. This certification serves as a testament to Midway's commitment to upholding top-notch quality practices, guaranteeing that each component they produce adheres to the most stringent standards of excellence. By choosing Midway as the manufacturer for rotary die, gear, and anvil pieces, businesses can have peace of mind knowing that they are working with a company that places a high emphasis on quality.

Midway's commitment to superior quality extends beyond just certification. They have a team of skilled professionals who are dedicated to maintaining the highest level of excellence in every component they produce. Midway team members are committed to quality standards because they understand the significance of consistency in production processes. By ensuring that all rotary die, gear, and anvil pieces meet the highest standards, Midway team members help businesses eliminate variations in quality and achieve a smoother and more effective production process. Their dedication to precision engineering and rigorous quality control processes guarantees that each component is crafted to perfection, resulting in cost savings, increased productivity, and superior end products. Working with Midway team members not only simplifies the supply chain and reduces logistical complexities but also allows for better customization and compatibility. Businesses can trust Midway as a reliable partner for maintaining consistent quality and delivering components of the highest standard.

Furthermore, Midway understands the unique needs of businesses that rely on rotary dies. They offer a wide range of customization options, allowing businesses to tailor the components to their specific requirements. Whether it's the size, shape, waste removal, or material, Midway can accommodate various customization needs, ensuring a perfect fit and optimal performance.

In conclusion, Midway is the trusted partner for businesses seeking superior quality in rotary die, gear, and anvil pieces. With their ISO 9001 QMS Certification and commitment to customization, businesses can rely on Midway to deliver components of the highest quality.

ISO 9001 QMS Certification: Ensuring Quality Standards

ISO 9001 QMS Certification is a testament to Midway's commitment to maintaining superior quality standards. This certification is internationally recognized and verifies that Midway has implemented a robust quality management system.

By achieving ISO 9001 QMS Certification, Midway demonstrates that they have established processes and procedures to consistently deliver products that meet customer requirements and comply with applicable regulations. This includes the manufacturing of rotary die, gear, and anvil pieces, where quality consistency is crucial.

ISO 9001 QMS Certification also ensures that Midway continuously monitors and improves their quality management system. They undergo regular audits to ensure compliance and make any necessary adjustments to enhance their quality practices. This commitment to continuous improvement further guarantees that businesses can rely on Midway for components of the highest quality.

In summary, ISO 9001 QMS Certification reinforces Midway's dedication to maintaining superior quality standards in the manufacturing of rotary die, gear, and anvil pieces. It provides businesses with the assurance that they are partnering with a manufacturer that values quality and continuously strives for excellence.

Conclusion: Elevate Your Production Quality with Midway

In conclusion, sourcing all your rotary die, gear, and anvil pieces from Midway is the key to achieving superior quality in your production process.

By having a single manufacturer for these components, businesses can maintain consistent quality throughout the manufacturing process. This ensures reliability, efficiency, cost savings, and improved overall productivity. The performance and functionality of the end products are also enhanced when all the components are precisely manufactured and fit together seamlessly.

Midway stands out as the best choice for businesses in need of superior quality. With their ISO 9001 QMS Certification and commitment to customization, they offer the assurance and flexibility that businesses seek. By choosing Midway as your partner for rotary die, gear, and anvil pieces, you can elevate your production quality and achieve the desired results.

Don't compromise on quality. Choose Midway for all your rotary die, gear, and anvil needs and experience The Midway Difference in performance and reliability.

*This content was written with the help of AI

.png)

.png)