Why Choose Solid Rotary Die Cutting for Manufacturing?

Explore the unmatched precision and efficiency of solid rotary die cutting and why it's revolutionizing manufacturing processes.

Understanding Solid Rotary Die Cutting: A Primer

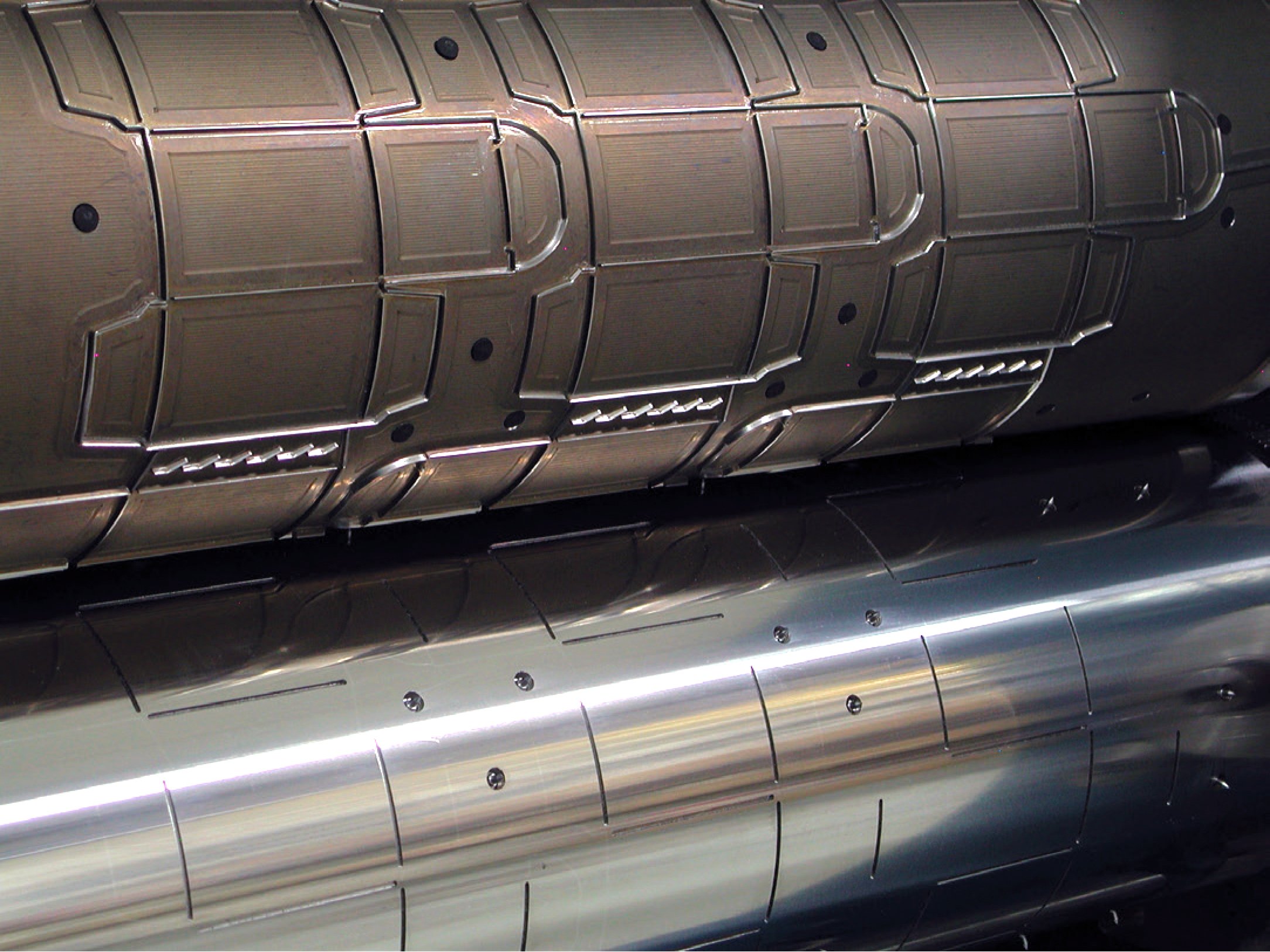

Solid rotary die cutting is a process that utilizes a cylindrical die on a rotary press to cut, perforate, and shape materials. This method is particularly effective for high-volume production runs, where precision and speed are critical.

The process involves a continuous web of material being fed into the rotary press, where it passes through a pair of rotary dies. These dies are precision-engineered to ensure consistent cuts and patterns, making it ideal for industries requiring high accuracy and repeatability.

Comparative Advantages: Solid Rotary Die Cutting vs. Steel Rule Dies

While steel rule dies are commonly used for low to medium volume production, they often fall short in terms of precision and durability compared to solid rotary dies. Steel rule dies are made from a flat sheet of steel, which can lead to inconsistencies in cutting over time.

Solid rotary die cutting, on the other hand, offers superior precision and longevity. The rotary dies are made from solid steel, which ensures a longer lifespan and consistent performance, even in high-volume production settings.

Enhanced Precision and Consistency in Production

One of the standout features of solid rotary die cutting is its ability to deliver unparalleled precision. The solid steel construction of the rotary dies ensures that each cut is exact, reducing the margin of error significantly.

This level of precision is particularly beneficial for industries that require intricate designs and tight tolerances, such as the electronics and medical device sectors. Consistency in production is also enhanced, as the rotary dies maintain their sharpness and accuracy over extended periods of use.

Cost-Effectiveness and Time Efficiency

Although the initial investment in solid rotary die cutting equipment may be higher than other methods, the long-term benefits outweigh the costs. The durability of solid rotary dies means fewer replacements and less downtime, translating to lower maintenance costs.

Additionally, the high-speed operation of rotary die cutting significantly reduces production time. This increased efficiency allows manufacturers to meet tight deadlines and increase their overall output, making it a cost-effective choice in the long run.

Applications and Industries Benefiting from Solid Rotary Die Cutting

Solid rotary die cutting is versatile and can be applied across a wide range of industries. In the packaging industry, it is used to create complex box designs and labels with high precision. The automotive industry benefits from its ability to produce gaskets, seals, and other components with exact specifications.

The healthcare sector also utilizes solid rotary die cutting for the production of medical devices and diagnostic tools, where precision is paramount. Additionally, the electronics industry employs this method for creating intricate circuit boards and other components that require high levels of accuracy.

*This content was written with the help of AI

.png)

.png)