Understanding Manufacturing Terminology for Narrow Web Rotary Dies

Explore the essential manufacturing terminology related to narrow web rotary dies in this informative blog post.

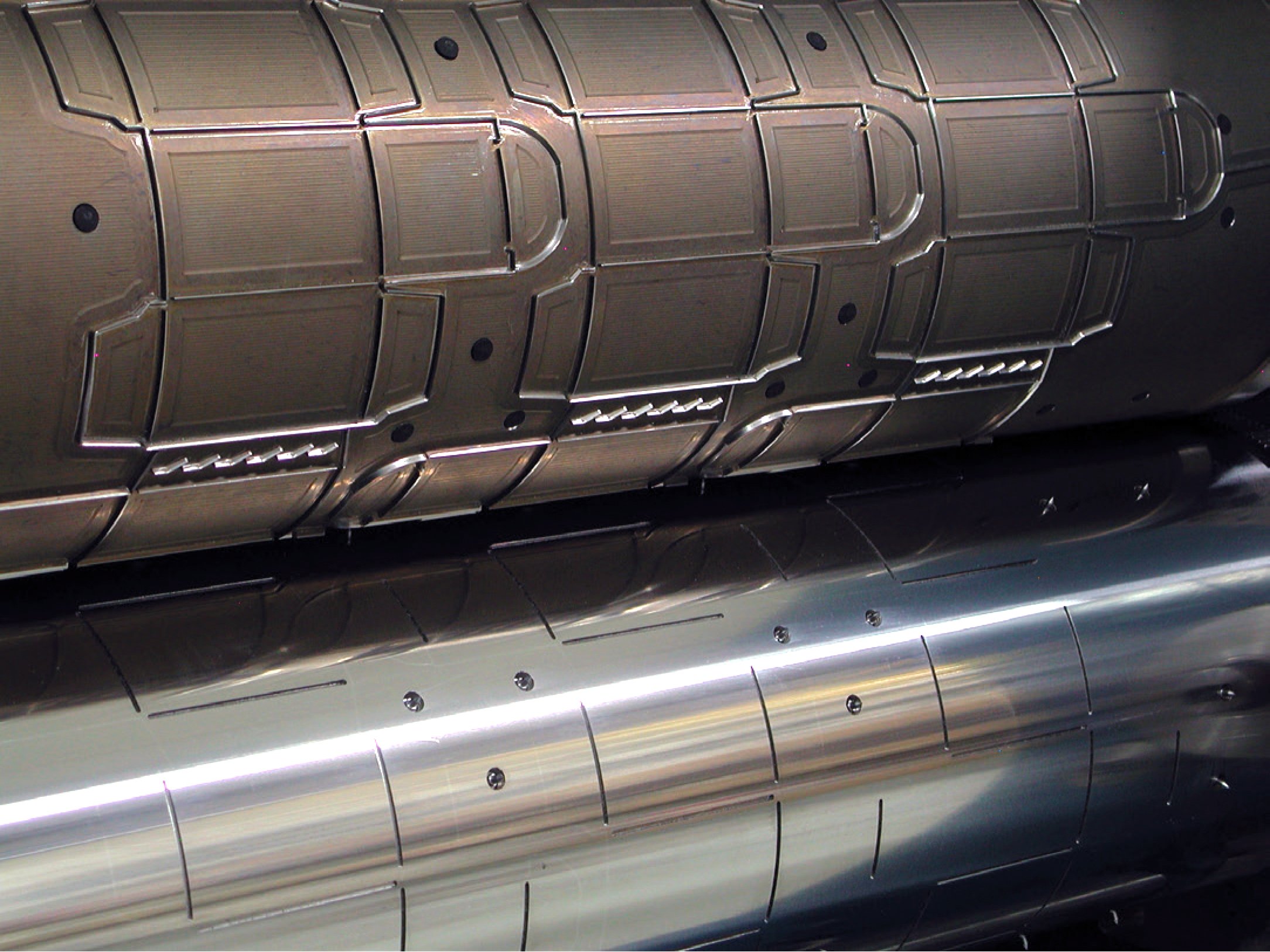

Key Components of Narrow Web Rotary Dies

Narrow web rotary dies consist of several key components that work together to perform precise and efficient die cutting. These components include:

- Cutting cylinder: The cutting cylinder is responsible for holding the rotary dies in place and rotating them during the die cutting process.

- Anvil cylinder: The anvil cylinder provides the necessary support for the material being cut and ensures clean and accurate cuts.

- Die plate: The die plate contains the cutting edges that shape the material into the desired form. It is typically made of durable materials like steel or brass.

Understanding these key components is crucial for optimizing the performance of narrow web rotary dies and achieving high-quality die cutting results.

Common Terms Used in Narrow Web Die Cutting

When diving into the world of narrow web die cutting, it's important to familiarize yourself with some common terms used in the industry. These terms include:

- Kiss cutting: Kiss cutting refers to a process where the die cuts through the top layer of material without cutting through the underlying substrate. This technique is often used for creating labels and stickers.

- Matrix: The matrix is the waste material left after the die cuts through the desired shape. It needs to be properly removed or stripped away from the final product.

- Register: Register refers to the proper alignment and positioning of the cutting edges with the printed design on the material. Achieving accurate register is crucial for producing visually appealing and precise die cut products.

By understanding these common terms, you can effectively communicate with professionals in the narrow web die cutting industry and better comprehend the processes involved.

Understanding Rotary Die Tooling

Rotary die tooling plays a vital role in narrow web die manufacturing. It refers to the various tools and equipment used in the production of rotary dies. Here are some key aspects to understand about rotary die tooling:

- Die material selection: The choice of die material depends on factors such as the type of material being cut, the desired cutting precision, and the expected die life. Common die materials include steel, carbide, and engraved brass.

- Die sharpening and maintenance: Regular sharpening and maintenance of the rotary dies are essential for ensuring optimal cutting performance and prolonging the die's lifespan. This includes removing any buildup or debris that may affect the cutting edges.

- Die storage and organization: Proper storage and organization of rotary dies are crucial for maintaining their quality and preventing damage. Storing them in a clean and dry environment and using protective covers can help preserve their integrity.

By gaining a deeper understanding of rotary die tooling, you can make informed decisions regarding die material selection, maintenance practices, and storage methods.

Quality Control Measures in Narrow Web Die Manufacturing

To ensure the production of high-quality narrow web rotary dies, various quality control measures are implemented throughout the manufacturing process. These measures include:

- Material inspection: Thoroughly inspecting the materials used for manufacturing the rotary dies to ensure they meet the required specifications and standards.

- Dimensional accuracy checks: Verifying the dimensions of the rotary dies at different stages of the manufacturing process to ensure they align with the design requirements.

- Performance testing: Conducting performance tests on the rotary dies to evaluate their cutting precision, durability, and overall functionality.

- Quality assurance documentation: Maintaining detailed documentation of the manufacturing process, including material certifications, inspection reports, and test results, to track and monitor the quality of the rotary dies.

By implementing these quality control measures, manufacturers can deliver narrow web rotary dies that meet the highest quality standards and provide reliable performance.

Innovations and Trends in Narrow Web Rotary Die Terminology

The narrow web rotary die manufacturing industry is constantly evolving, with new innovations and trends shaping the terminology used in the field. Some notable innovations and trends include:

- Laser die cutting: Laser die cutting technology has gained popularity in recent years due to its ability to achieve intricate cuts with high precision and speed.

- Digital workflow integration: The integration of digital workflows in narrow web die manufacturing has streamlined processes, improved efficiency, and provided greater design flexibility.

- Sustainability initiatives: With growing environmental concerns, manufacturers are increasingly adopting sustainable practices in die manufacturing, such as using eco-friendly materials and optimizing energy consumption.

- Automation and robotics: Automation and robotics are revolutionizing the die manufacturing industry by enhancing production speed, accuracy, and consistency.

By staying up to date with these innovations and trends, professionals in the narrow web rotary die manufacturing industry can leverage the latest advancements to improve their processes and deliver superior products.

*This content was written with the help of AI

.png)

.png)