Midway Service

Past Experiences Got You Down?

Meet The Midway Difference

Supportive Service

We're committed to working with our clients, not against them.

Reliable Products

We're dedicated to crafting only the highest-quality dies, nothing less.

Exceptional Expertise

We know a thing or two because we've innovated a thing or two.

Dedicated to Service Through & Through

In our mission

Our mission statement "Converting Innovation Into Productivity" holds significant meaning for us within the rotary die manufacturing industry. In this context, innovation refers to the continuous improvement and development of new technologies, processes, and products within the industry and at Midway. By focusing on innovation, we can stay ahead of the competition and meet the ever-evolving needs of our customers. However, innovation alone is not enough. The true value lies in converting these innovative ideas into tangible results and increased productivity. This mission statement emphasizes the importance of not only coming up with new ideas but also implementing them effectively to drive efficiency, quality, and overall success in the rotary die manufacturing industry.

In short, our mission is simple, effective, and focused.

In our vision

At Midway, our company vision is centered around growth, expansion, and innovation. We are committed to growing our business and expanding our reach to provide more converting solutions to our customers. Our goal is to always stay ahead of the curve by continuously innovating and adapting to the ever-changing market landscape. With a focus on excellence and customer satisfaction, Midway is dedicated to pushing boundaries and setting new standards in the industry. Join us on our journey as we strive to be the leading provider of cutting-edge solutions for all your converting needs.

In our process

At Midway, we pride ourselves on our commitment to providing exceptional support to our customers throughout their sales journey. From the moment they first interact with our products to long after their purchase, we are dedicated to ensuring their satisfaction and success. Our team of knowledgeable professionals are always available to answer any questions, address concerns, and provide guidance every step of the way. Additionally, we understand the importance of our own internal production journey and strive to optimize efficiency and quality in our process. By continuously improving our operations and streamlining our workflows, we are able to deliver superior products and services to our valued customers. Our dedication to excellence in both customer support and production is what sets Midway apart in the industry.

Need More

Reassurance? Proof? Confidence?

At Midway Rotary Die Solutions, we manufacture premium tool steel rotary dies. They aren't always the cheapest, but in most cases, they are the least expensive in the long term. If you're challenged to reduce tooling costs, read on. Reducing tooling costs means thinking different. It means considering all-in costs, far beyond the up-front cost of the tool. All-in costs include -

• Initial tool cost

• # Parts produced before tool needs sharpening

• # Resharpenings before tool is used up

• Cost to ship to/from your die vendor for each resharpening

• Setup time (and lost production) for each occasion when tool is removed for resharpening

Add the total number of parts produced for the life of a tool and divide by the total all-in costs of the tool to determine the cost per part of the tool. A real-world comparison of the cheapest tool and the Midway premium tool when looking at all-in costs is shown below.

The Midway Die delivers a 39% savings per part produced - Amazing Savings!

.png?width=573&height=422&name=Updated%20Calulator-1%20(1).png)

CHALLENGE

Based on outstanding work with a long-time Health Care customer, a Medical Converter earned a new project, their first-ever transdermal product. They regularly perform complex medical converting of a variety of materials, including hypoallergenic medical tapes, films, non-woven fabrics, foams and other flexible materials used in the production of medical devices, equipment and skin contact application.

Working with a controlled substance material for the first time, the converter’s engineering team designed a die layout with extremely close nesting to minimize waste, because waste disposal of a controlled substance was the highest cost of the entire job. After the die vendor manufactured the die to spec and they began running the job, the die didn’t work. They experienced two critical issues they couldn’t resolve:

- Ragged cuts, which couldn’t even be resolved at slower than required press speed

- Excess part rejection, meaning extreme unplanned controlled substance waste

Taken together, this meant what had started as a highly profitable project quickly turned negative. The converter reached out to the product manufacturer for help, who suggested they contact Midway because of our familiarity with the material.

SOLUTION

The Midway Engineering team went to work on the challenge. Our familiarity with the material and the firm’s press helped us identify the issue and develop a solution. Evaluating the die layout and planned press speed, the Midway technical team recommended two primary modifications:

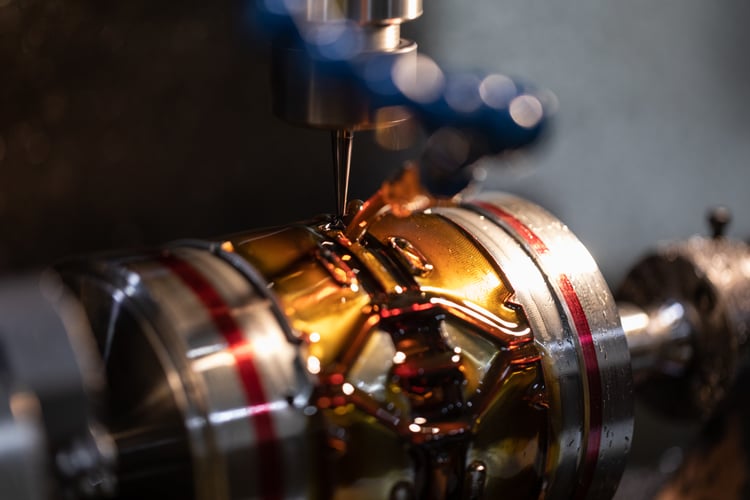

- Reconfiguring the die layout to eliminate parts being cut simultaneously across the entire width of the die; this allows increased press speeds while maintaining part quality. While parts are farther spaced, the calculated yield increased.

- Machine sharpening to produce unparalleled consistency and uniformity of blades, further enhancing part quality with tight-tolerance materials with the added benefit of equal wear across the die, enhancing die life.

Because of the unconventional layout, Midway guaranteed the converter that if the die didn’t perform as expected, they could return the die for a refund.

RESULTS

Midway sent a technical representative to be on-hand at the converter for the die’s initial run. The job ran flawlessly. The parts were on-spec. The press operator and production manager were amazed that by the end of the first shift, yield surpassed the converter’s original projections by 17%. Best of all, the costly waste was reduced by over 10%, saving money and also mitigating risk the waste material could be disposed of improperly by mistake.

“With Midway Rotary Die as our die partner, we’re aggressively going after even more challenging medical work,” the firm’s head of New Product Development told Rich Seeley, former president of Midway. Sharing more of the good news with Rich, he continued, “Our profitability on this job not only beat projections, but it’s our most profitable job by far.”

At Midway Rotary Die Solutions, we take a different approach to serving our customers. We listen and develop solutions that address your unique converting challenges with the goal of increasing the profitability of your projects. Experience The Midway Difference:

• 100% of our dies are high-strength long-lasting tool steel

• 100% of our dies are fully-hardened (through-hardened), using in-house heat treat and the option for deep-cryogenic treatment

• 100% of our dies benefit from a Design Review to enhance yield and reduce waste – we don’t just build the die you’ve been getting, we build it better

• 100% of our dies are optimized for the press they run on and material you cut – we customize blade angle, rout depth, cavity spacing and blade sharpness

• 100% of our customers are assigned a contact at Midway who answers your questions and assures your project is handled correctly from quote to shipment

• 100% of our dies are tested using customer-supplied material prior to shipment to make sure they perform as promised – with sample cuts included with the die

• 100% of our dies are customer satisfaction guaranteed